A TIE Pilot's helmet

The father's day took place again and brought some Lego with it. I had seen a couple of photos of these helmet or bust sets before, but I wasn't sure if I had witnessed one with my own eyes. Not that it told much during this corona season, as I spent even less time in toy shops than before. The helmet was going to be stylish and at this point it was spread out into six bags of pieces.

Constrconstrconstrconstr

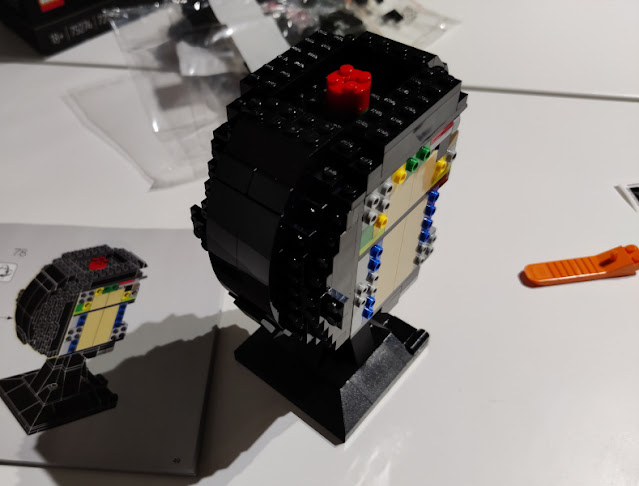

Of course I started building the same evening, and in my delusions of grandeur I thought I'd be done in one sitting. The first bagful of pieces resulted in a colourful core of the helmet.

The second bagful gave us the stand and the neck curve for the helmet. Some dedicated builders have been doing these round shapes just for fun, I found it pretty complex work.

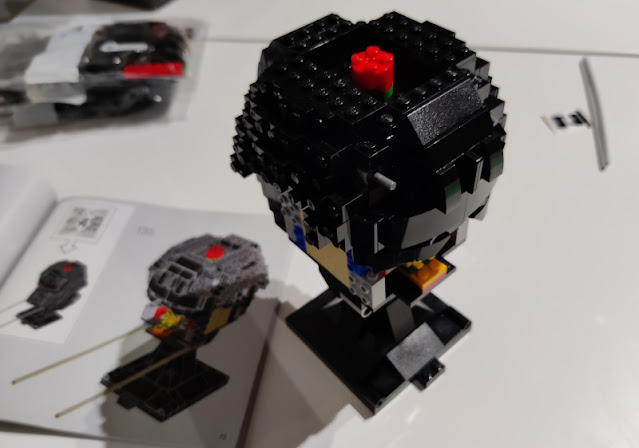

While building the subassemblies I didn't guess that these were going to end up as the forehead and the lenses of the mask.

Interestingly the grimacing Stormtrooper-mouth was a bit difficult to keep in check, thanks to the angles and many hinged connections. It behaved decently in the end, even though I managed to drop those off a couple of times later on.

When I was wrapping up the first evening I had reached the end of the left ear/cheek/chin section. This was pretty slow work, but I wasn't rushing, because I wanted to enjoy building in peace. The pilot was missing her chin, while there were a couple of part bags left still.

Evening 2

On Monday evening I sat again to build. Taught by the left side, the right side went much quicker and easier, as these symmetrical builds tend to go. Again the biggest problem was the jaw-complex's final part that had to be installed much deeper (closer to the mouth) than what I imagined from the picture in the instructions. That's why I had gotten the mouthpiece fall off a few times while working on the left jaw.

The most beautiful printed radar dishes ever were to decorate the forehead of the pilot. I could want a few spares of these pieces, just to own a few.

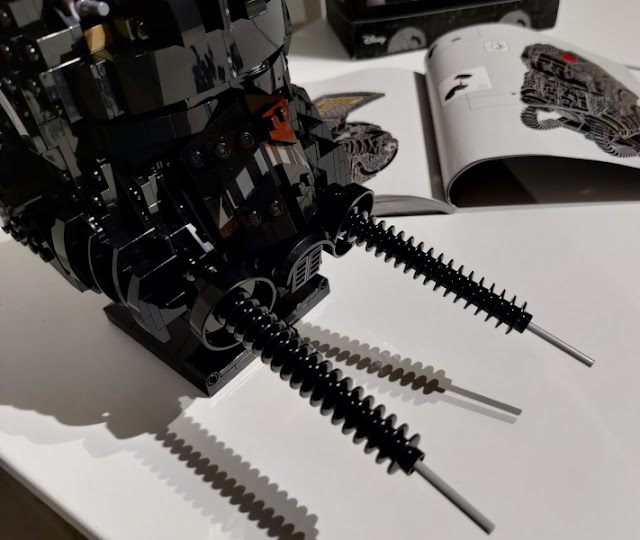

Everybody here knew that the Imperial Navy's gorgeous TIE series ships did not, according to the old canon, contain life support so the pilots had pressure suits. At this point the jaw's air pipes looked a bit more like the insulators one can usually see next to high-voltage power lines.

Finished

After a bit more than two hours of tinkering the bust was finished. These shiny black pieces were impressive-looking, they just left me wondering if I had left too many fingerprints. Just like with the Metal Earth Models, an extra source of concern.

By the Emperor, it was magnificent!