The outer shell

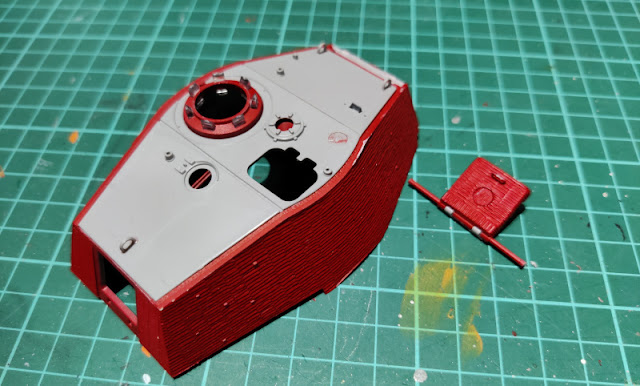

At long last my King Tiger project rose to a new level. I was a bit concerned about the shell of the turret and its insides fitting together as I had just found the hull fitting to be a major challenge. Like a few other pieces so far the turret's top plate was a bit too flat compared to the angle that was required by the walls. So I first glued it on from one end, had that bond cure, and then proceeded forcing the rest in place. This didn't need much force, which was a positive thing again.

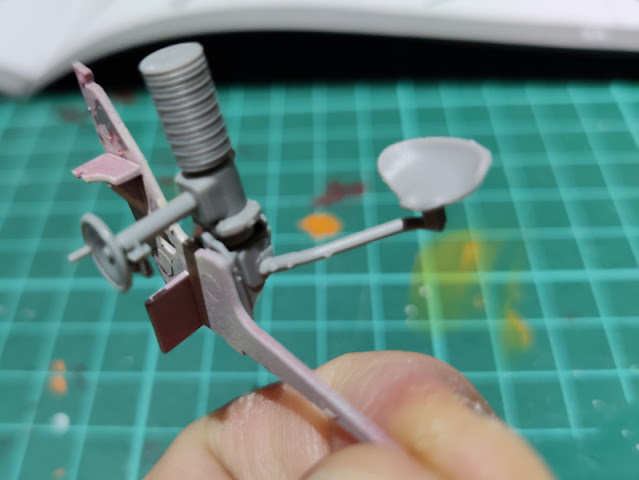

The insides of the turret were going to be somewhat crowded, there were numerous hatches and everything needed a piece or seven attached to it. Next to the fire extinguisher you could see a pretty common detail, the Nahverteidigungswaffe or its inner tube, but all this other stuff... wow!

Masking and painting the commander's cupola's periscopes sounded very hardcore at this point to me. A very complex setup, with all the pieces, but it also was so very much cooler than the typical solutions I've encountered so far.

Both the inner and outer sides of the turret were progressing slowly and carefully, a hatch, hoop and a handle at a time. My slowness came mostly from the cleanup of the tiny bits.

Now I had to choose whether I wanted the gunner's hatch open or closed: if you were going to build it open, you needed to use an extended piston x; if you wanted it to be closed you had to use the short/retracted piston y. Sadly just about everything inside the turret remained a mystery to me, just like in the combat compartment.

Funny thing, the commander's cupola's periscope protectors were one short (piece A2, the second of two of those needed). I retraced my steps through the whole instruction manual and what I had built, in case I had accidentally and stupidly used an A2 when I needed something else.

No, I had not, there were no wrong pieces anywhere, this was the only place where this piece was needed. Where could I lose a bit like that and why? Oh well, it was lost and I could not find it, so the tank was going to go into battle with a missing bracket over a periscope head.

The commander's MG rack I could've left off, especially as there wasn't going to be a machine gun to be attached to it. I still did it, to compensate for the other failures. Or to ultimately highlight them, we'd find out (a lot) later.

The turret's outside was now as complete as it was going to be at this point. It took a foul number of evenings, mostly due to the impressive amount of very small pieces that needed a good amount of cleanup. I left the track link -hanging hooks off on purpose, I did not intend to use them at all. My motive for that was that if I was going to have to swear and use some force when attaching the turret's outer shell onto the rest of the turret, I didn't want to have to worry about these details on top of everything else.

This wasn't anything I could've called dry-fitting the turret, as the outer shell of the turret lazily lounging on top of the tank's deck wasn't a realistic thing. It was still nice to see that all these slow, tiny steps ultimately showed some actual progress. After weeks of staring at them, that is.