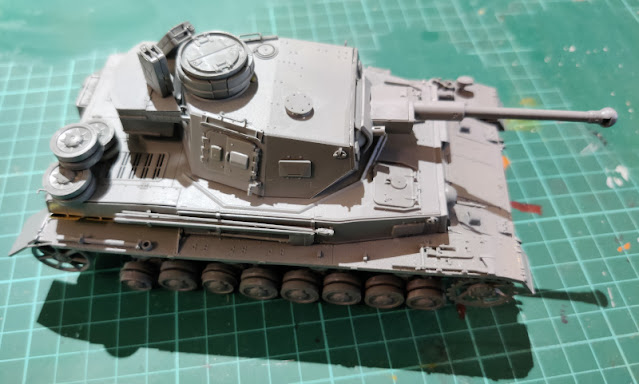

Trying out uncle Night Shift's methods

The occasionally mentioned work Slack's miniature painting channel had a colleague asking about my T-34 turret, if I had made the cast texture using Night Shift's method and they said they'd used it on some concrete floor basing on WH40k bits and that the method was pretty simple.

That encouraged me to try out these two methods for creating the steel texture.

Method 1: liquid cement and a stiff brush

Because all new experiments and such should always be tried out in an invisible or easily hidden place, I started from the turret's left front corner. I had an old and mistreated brush that I was going to throw away. It had its chance to serve the last time before being released.

I used the brush to spread the Tamiya's thin cement like paint and left it for a short bit to do its thing to the plastic. Then I stabbed the plastic with the brush pretty randomly. Softened by the glue, the plastic deformed gently. This effect looked pretty neat so I continued around the turret's vertical bits.

From the turret I proceeded to the hull full of tools and did what the space allowed me. In the first photo the surface was just softened by the glue, in the second photo there were some markings caused by the brush-stabbings for comparison. I also processed the Panzerwanne's sides even if they really weren't going to be much seen in the final model.

Excitedly I also did this on the front- and rear armour plates. The vertical or vertical-ish surfaces like the decks I didn't touch.

This final photo showed some brown tint on the rear armour and that was caused by impurities on my ancient paintbrush that started affecting my operation only in the end. I thought that this'd dry mat after drying by the next day, but I was wrong. The glue-affected bits remained glossy which was a bit confuseing, but didn't affect the end result.

Method 2: putty diluted with liquid cement

I truly could've left it here and be happy, but while prototyping I wanted to try the next stage as well. As I didn't currently own any of Tamiya putty that mr. Kovac recommended, but Mr Hobby's Mr White Putty that I have never liked too much as it started kicking quickly and immediately after getting exposed to air. I trusted that diluting it with the thin cement the drying time would be somehow slower.

Using my old jar lid as a mixing palette I used some putty and quickly mixed glue into it. As the putty was so eager to kick, I used more glue than I expected to need, so I could get it into a paintlike consitency to be brush-appliable.

|

| Dried glue-putty effect |

|

| Sanded-down glue-putty effect |

In the front of the tank I did my best to avoid going over the edges, so the result was more cautious than what a bit more experienced user would've achieved. Had I been more eager and daring, I might have used this on the radio operator's machine gun mount and more on the driver's periscope shield. On the first try I thought it was better to take it easy.

Working on the right side of the tank I was cautious of the antenna system and trusted in the method 1's texturing worked nicely enough on its own.

The left side had lots of junk attached, so I mostly concentrated on the areas where applying the glue-putty goo was safe.

None of these showed that after a bit of a break to let the stuff cure I sanded down all of these freshly textured sufaces with a sanding sponge. As it was now it looked pretty weird, but I had confidence in the power of paint making this make sense.