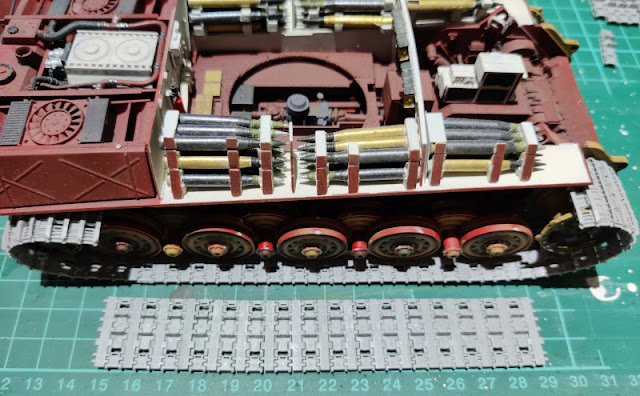

Some road wheelery

It may have been obvious that I left the tracks and friends purposefully (or because of my own stupidity) to the end of the project. Somehow, as a scale tank enthusiast I've felt a tiny bit of shame for having the "erf, here again" moment most often when working on the tracks.

Perhaps one of the reasons for my attitude problem came from the repetitiviness of this stage. First set up and then paint a large number of discs. Then a sick amount of track links need to be queued and glued - twice while you're trying to figure out the best rate of slack, or if the track should be pulled tight instead?

The inner road wheels

I detached all the eight inner road wheels and installed them. Not a single moment of pondering was had to decide which was to go where, as the road wheel camouflage was not planned in any way between the wheels, even less so with the hull.

Outer road wheels

The outer quintet of the road wheels didn't fit perfectly on either side of the tank, completely unlike the inner ones. I didn't want to use force and break anything off, so I thought I'd try to carefully jiggle them in a bit better.

With the wheels on I left them alone for a while. After the gluings had dried I washed the outer faces with brown. The sprue attachment spots you could see in the photos I was going to fix later on.

Locking bolts

I didn't actually know how to call these bits that kept the roadwheels in place. The long ones went in first (4 per side) to lock the inner wheels into their road arms, then the crowns alone (5 per side) to lock the outer road wheels in.

As I had painted the roadwheels and the bolt-things independently from each other, I had a pretty odd mix of them in my hands. I tried to pair them as sensemakingly as I could. A few of them matched their road wheels just fine, some somehow and a couple of them stuck out like a stick in something nasty. Washing and weathering were expected to hide this crime a bit.

Of the long bits I had only painted the tips, not the sides of the cylinders. Those were going to be touched up while I was to paint the outer rims of the road wheels. Kein Problem.

Tracks

Was this the moment where I was going to repeat how assembling the tracks themselves has always been the most uninteresting stage of tank modeling? The rubber band loops never stayed in one piece (or straight), the varying-lenght bits always ended up looking like trash and these individual link tracks took ages and were, like I said, tedious at best.

Once, almost 17 years ago now, I ordered a set of Friulmodels metallic tracks to a Jagdtiger. The vehicle also looked like it was done by me at that point. The tracks themselves were wonderful and weighed almost as much as life itself. Maybe I could try their products with a simpler track type than this. In fact, in my delusional mind I have been dreaming of a new Hummel as I somehow never completed the Dragon models 1:35 one back in the day. Couldn't recall why, exactly, I didn't finish the painting.

|

| 📷 2005 CE |

I also haven't still found the optimal (for me) way to assemble the tracks. Most typically I've just laid them out, glued, connected the loop and slapped the thing on while still posable, and left the painting to be done in situ.

An implementation idea

This time I felt like trying someting else: I'd at least assemble the ground-hugging straight parts separately and let them dry completely. Then, while fighting the schedule, I'd try to get the rest of the track done before the glue sets, and get each track in place with the assistance of unattached drive sprockets. There the track could find its shape.

Because the whole setup could be popped out by taking the drive sprocket out as well, it could be calmly painted without a worry. After all the paintings were done and paintjobs dry, the reinstallation should be as simple (or swear-inducing) as detaching, and gluing the first and last track links together would be child's play.

The assembly process

My King Tiger's tracks came in two bags: track links in one bag and their connectors in another one. Judging by a quick dry-fit, they did fit together pretty nicely.

My first assembly session didn't offer much time for the tracks, which meant I got almost the full first ground lenght done. Like I was thinking before, I let this to dry flat. At this point I was thinking that maybe I'd improve my chances by assembling four of these straight runs: two against the ground, two slightly longer bits for the return trip. Then I could do the curvy drive- and idler ends separately.

I really couldn't believe that I would have the time during my hobby time to build a full track, not to mention two. The glue's drying time set tightish limits to how slow I could be in my doings. The more I could decrease that risk by spawning subassemblies, the safer I was going to be. That'd take more time, of course, but maybe the result would be better and my nerves less ruined.

Front loops and the left track

To get the first run done I measured roughly, how many links were still missing from the bottom straight. I extended it by about half a dozen links, which got my ground-touching track part to cut at the center points of the frontmost and rearmost road wheels.

The next track stage I started working on by laying the idler wheel curves. I pulled the "five links" count from my hat and after the glue had cured a bit, I laid the runs onto the idler wheels. Maybe they could've been a link shorter each.

While the curve was setting into shape, I assembled the short straight bit that connected the curved part and the ground part. Eyeballing I set a three-link run and the connectors

My guess seemed decent, because if I had made te curve shorter the track would've been set at an unnatural edge (I had done those, too, in the past), here the arc could've been a bit shorter. Or maybe I was going to hopelessly build a track that followed the wheels tightly. That was quite unlikely.

The rear loop

For the idler wheel's loop I made a shorter run and set it to dry onto the idler wheel. At this point I still could play a bit with the lenght of the rising rear track part, using it to affect the rotations of the idler wheel and the drive sprocket.

At this point the track of mine seemed pretty decent. The rear loop could've been a tiny bit longer, even, so both loops would've descended nicely towards the road wheel for the upper half of the loop.

This is the very unscientific way I measured the lenght of the remaining track, by measuring against the gap. Someone smart may have noticed what my mistake was (again).

Repeat on the right side

As usual, implementing the second copy was powered by (relative) familiarity and getting up to speed. Of course I had prepared a couple of bits for the right track while working on the left one. Now the measures were pretty much known and as I have said many times, getting started on these made the progress actually pretty rapid.

They didn't end up identical, the lower one here looked better in my opinion, but maybe they'd both be acceptable. Neither of them was locked into one piece, the unglued connections were behind the drive sprockets.

No comments:

Post a Comment